- Thermoplastic profiles are revolutionizing modern manufacturing, offering exceptional versatility and adaptability across diverse industries.

- Their advantages—lightweight design, durability, recyclability, and innovative shaping capabilities—make them essential in automotive, aerospace, construction, and medical industries.

- Technological advancements, such as nanotechnology and 3D printing, continue to widen the scope and enhance the properties of thermoplastic profiles.

- Despite their strengths, careful consideration of material selection and processing requirements is crucial for optimal performance.

- Introduction to Thermoplastic Profiles

- Key Applications Across Industries

- Advantages of Thermoplastic Profiles

- Technological Innovations Enhancing Thermoplastic Profiles

- Sustainability and Environmental Impact

- Challenges and Considerations

- Future Outlook

- Conclusion

In today’s high-stakes manufacturing environment, efficiency and adaptability are critical for business success. Thermoplastic profiles are increasingly the material of choice, offering manufacturers the flexibility to design and produce intricate forms without sacrificing strength or reliability. These profiles, which are made from polymers that soften when heated and harden upon cooling, enable the mass production of parts with highly specific dimensions and tight tolerances. Companies across industries rely on thermoplastic profiles Norwalk, CA, to meet evolving consumer and regulatory demands. Thanks to their unique ability to be repeatedly molded and shaped, thermoplastic profiles deliver substantial cost savings and reduce production lead times, making them essential for both rapid prototyping and large-scale manufacturing.

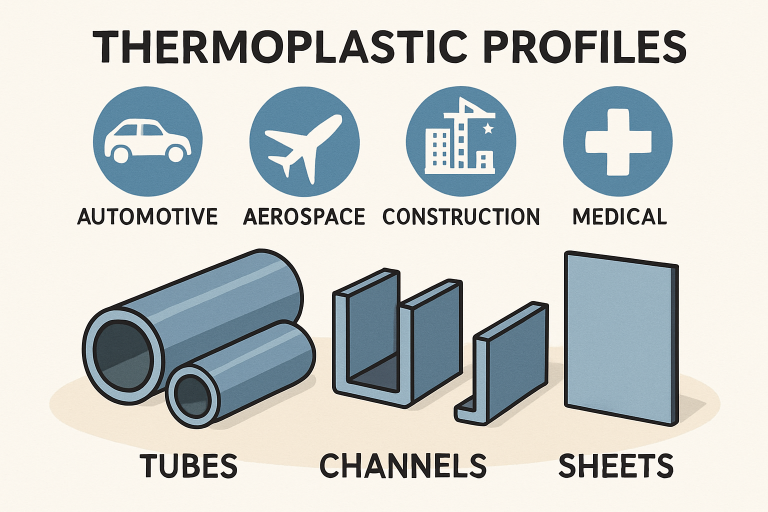

Thermoplastic materials are increasingly replacing metals and thermoset plastics due to their waste-reducing properties and enhanced performance. Advances in materials science have produced thermoplastics suitable for high-temperature and chemically demanding environments. They are widely used across industries: in automotive for durable air filters, coolant channels, and battery casings; in aerospace for lightweight interior components that improve fuel efficiency; in construction for roofing, insulation, and architectural elements; and in medical devices for hygienic, easily sterilized products like IV bags and diagnostic housings, supporting safer and more cost-effective healthcare solutions.

- Lightweight Construction: Thermoplastic profiles preserve structural integrity while significantly reducing weight, an advantage critical for industries committed to energy savings and efficient logistics.

- Design Versatility: The plasticity of these polymers at elevated temperatures enables the formation of complex, intricate designs that would be prohibitive with conventional materials.

- Exceptional Durability: Thermoplastics are engineered to resist impact, moisture, UV rays, and corrosive substances, ensuring longevity even in harsh environments.

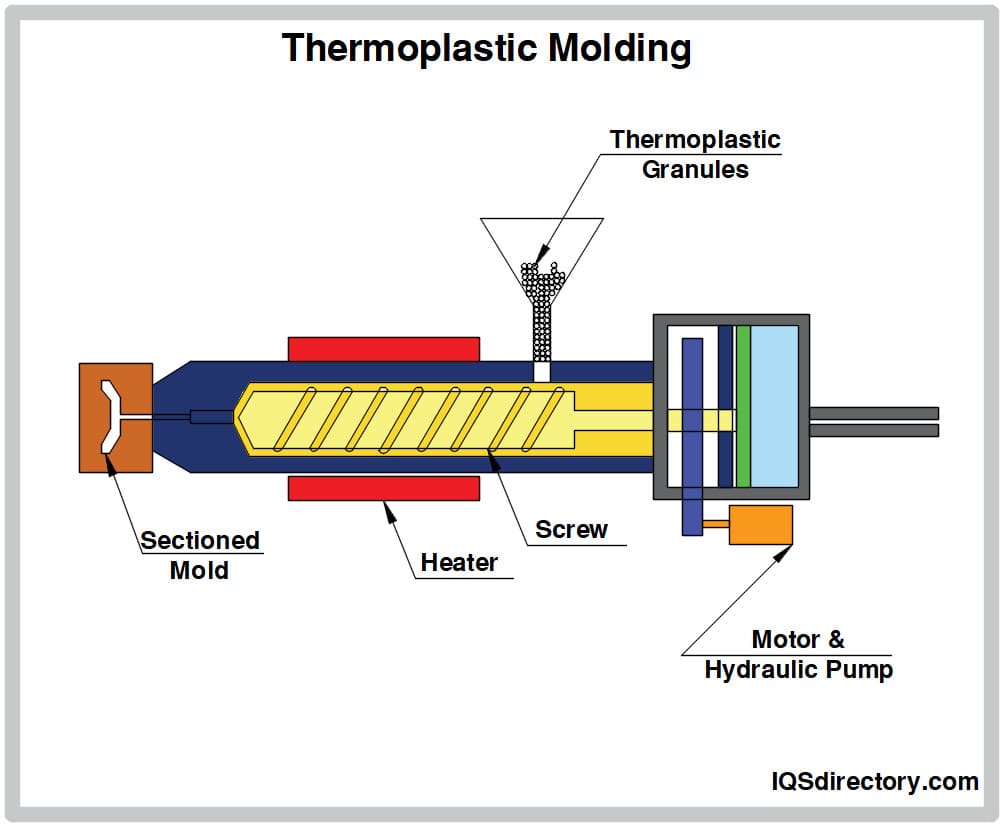

- Production Efficiency: Advanced extrusion, injection molding, and thermoforming methods slash production times, reduce costs, and enable large-volume manufacturing without compromising quality.

According to ScienceDirect, the mechanical and economic advantages of thermoplastics enable companies to more easily embrace agile manufacturing principles and quickly adjust to changes in product demand.

These benefits make thermoplastics an increasingly popular choice across industries ranging from automotive to aerospace. Their adaptability ensures that manufacturers can meet both performance requirements and sustainability goals simultaneously.

Integrating nanofillers has been a game-changer for nanocomposite thermoplastics, enhancing strength, stiffness, and thermal stability in profiles designed for high-demand applications. Manufacturers have found success in leveraging these improvements for next-generation automotive, aerospace, and consumer product components.

The rapid evolution of additive manufacturing has paved the way for custom thermoplastic profiles, tailored to unique geometries or low-run product development. Engineers can now prototype and test functional designs faster than ever, taking ideas from concept to market at record speeds.

Automated extrusion and thermoforming are transforming the production floor, reducing error rates and making the labor force more efficient. As a result, manufacturers are better equipped to respond to labor shortages while ensuring quality control.

- Recyclability: Thermoplastics are inherently recyclable. Damaged or obsolete parts can be remelted and reformed, encouraging the circular use of materials and reducing landfill contributions, as noted in discussions of plastic recycling and resource recovery on Britannica.

- Lower Transportation Emissions: Lightweight alternatives reduce vehicle and aircraft loads, limiting fuel consumption and curbing greenhouse gas emissions throughout the transport phase.

- Eco-Conscious Material Science: Advanced formulations now prioritize both performance and environmental friendliness, helping companies reach stricter regulatory and sustainability targets.

These environmental benefits are sparking further innovation in how industries measure and minimize their carbon footprints.

- Material Selection: A thorough understanding of mechanical, thermal, and chemical demands is necessary to select the right thermoplastic for each application, as mismatched selections can undermine performance and safety.

- Processing Complexity: Achieving optimal part quality requires meticulous attention to extrusion, molding, and cooling processes. Small variations can lead to warpage or reduced mechanical properties.

- Investment in High-Performance Materials: While standard grades are affordable, high-tech thermoplastics may command premium costs, requiring detailed lifecycle and cost-benefit analyses before adoption.

The future for thermoplastic profiles remains bright, supported by tireless research into innovative materials, bio-based polymers, and high-function composites. The convergence of digital design tools with advanced material science is set to unlock new possibilities in lightweight structures and highly customized manufacturing. Ongoing collaboration between materials scientists and design engineers will play a decisive role in redefining global standards for efficiency, sustainability, and product innovation.

Thermoplastic profiles continue to underwrite the next generation of manufacturing, empowering companies to innovate with unprecedented speed and flexibility. By blending versatility, cost savings, and environmental responsibility, these profiles stand poised to shape the future of numerous industries as they adapt to global market demands and regulatory landscapes.