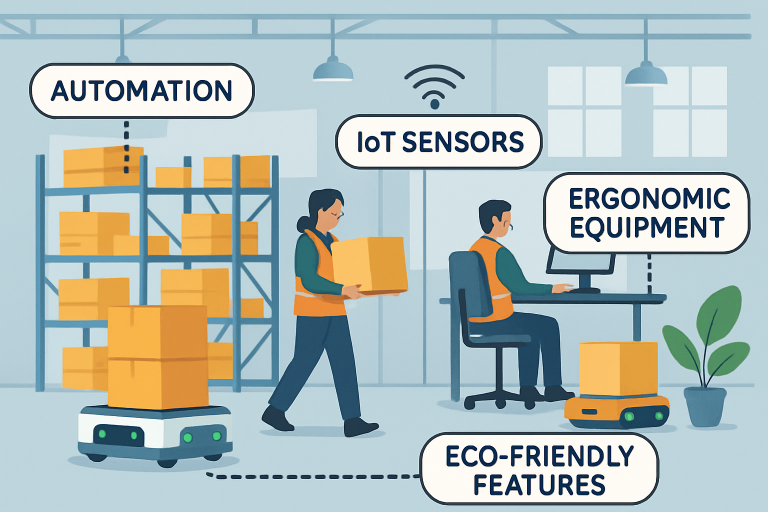

- Automation and robotics are revolutionizing material handling, reducing manual labor and increasing efficiency.

- Integrating IoT and smart equipment provides real-time data for better decision-making.

- Ergonomic designs and safety innovations protect workers and improve operational performance.

- Sustainable practices in material handling contribute to environmental responsibility and cost savings.

Today’s businesses are transforming at lightning speed, driven by the demand for quick fulfillment, higher productivity, and safer operations. As competition grows fiercer across industries, improving how materials and products move throughout a workspace has become essential for companies hoping to maintain or increase their market position. Improving material handling processes—such as how components, products, and supplies move throughout the workplace—is now central to maintaining competitiveness. Modern organizations are rethinking their logistics from the ground up, evaluating every facet from equipment selection to workflow optimization. Companies optimizing their operations prioritize not just cutting-edge equipment but also streamlined strategies for moving goods efficiently. Whether you’re managing a warehouse, retail hub, or manufacturing site, investing in reliable handling solutions, such as Blickle casters, can noticeably enhance productivity and workflow. The right handling tools reduce not only physical strain and fatigue but also the likelihood of costly errors and accidents, creating a safer, more supportive environment for every employee.

Modern material handling solutions are no longer just about transporting goods from point A to B. They’re about creating integrated systems that balance automation, data-driven insights, ergonomic safety, and sustainability. The integration of these elements helps businesses respond more quickly to shifting customer demands, sudden supply chain fluctuations, and unexpected market disruptions. By leveraging technology and smart design, organizations can create a safer, more resilient, and cost-effective workplace while reducing employee strain and minimizing operational bottlenecks. This multifaceted approach is fundamental for companies that want to adapt proactively and remain flexible no matter what challenges arise, all while supporting the well-being of their workforce and the environment.

Technological breakthroughs have positioned automation at the forefront of efficient material handling. Warehouses and production sites are increasingly utilizing Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) to automate repetitive, high-volume processes. These robots navigate busy spaces alongside human workers, efficiently transporting heavy loads, replenishing inventory, or delivering parts to assembly lines. Autonomous forklifts and robot-assisted picking systems have shown substantial reductions in logistical errors—fewer misplaced inventories, fewer human-caused accidents, and major improvements in speed and accuracy. Beyond reducing risks and boosting speed, automation enables human workers to focus on tasks that require problem-solving and adaptability rather than on simple, repetitive labor. According to The Wall Street Journal, companies that invest early in warehouse robotics often see double-digit productivity gains and significant labor cost savings. These benefits help organizations respond to labor shortages and demand fluctuations far more effectively than traditional models.

The Internet of Things (IoT) is transforming equipment and facility management in material handling. Smart sensors embedded in warehouse racks, forklifts, and even packaging materials allow continuous gathering and analysis of operational data. This data offers visibility into everything from equipment health and location to product condition and workflow bottlenecks. These IoT-based systems enable predictive maintenance, alerting managers to address wear and tear before costly breakdowns. Imagine a world where breakdowns are virtually eliminated and downtime is reduced to a minimum.

Additionally, real-time tracking of goods and assets reduces shrinkage, optimizes processing times, and supports seamless scaling during peak periods. Companies leveraging IoT solutions not only minimize downtime but also benefit from more accurate demand forecasting and resource allocation. As reported by Forbes, IoT adoption has become a hallmark of forward-thinking supply chains. IoT also fosters collaborative environments, connecting people, processes, and technology into a single, cohesive unit, paving the way for the “smart warehouse” of the future.

Efficient material handling doesn’t prioritize speed at the cost of worker well-being. Advances in ergonomic equipment design are reshaping how employees interact with tools, reducing fatigue and the risk of injuries. Modern adjustable workstations and lift-assist mechanisms are engineered to accommodate the diverse physical requirements of employees, reducing the risk of musculoskeletal disorders. Features such as anti-fatigue platforms, lift-assist devices, and adjustable handle heights protect workers from repetitive strain. These innovations make it easier for people of all ages and abilities to work longer, more comfortably, and with fewer disruptions.

Meanwhile, safety systems—like automatic shutoffs, improved machine visibility, and intuitive controls—ensure a secure work environment. In addition to reducing incident rates, modern safety features often include data-logging and alert systems that notify managers of unsafe conditions in real time. Employers who implement these innovations frequently experience fewer workplace injuries, higher employee retention, and improved morale—leading to more stable, productive operations. Organizations can even use these improvements to attract top talent, showcasing a commitment to the health and safety of every staff member.

Environmental stewardship has become an industry standard, prompting businesses to rethink their material-handling practices. Eco-friendly choices, such as energy-efficient conveyors and battery-powered vehicles, reduce emissions and operational costs. These environmentally responsible improvements not only support cleaner air and healthier communities but also help companies comply with local and international regulations. Flexible warehouse designs and material recycling programs further lessen environmental impact. By implementing green initiatives, organizations not only support global sustainability efforts but also strengthen brand reputation and enhance bottom-line profitability. According to The New York Times, many organizations now see sustainable logistics as a competitive necessity. Companies committed to sustainability are often better equipped to handle resource shortages and shifting environmental policies, making their operations more resilient in the face of global change. Investing in sustainable solutions also tends to pay for itself in the long run through lower energy bills and waste management costs.

Efficient material handling systems deliver measurable results across industries. For instance, a major retail chain transformed its order fulfillment by adopting modular conveyor and automated sortation systems. This upgrade enabled faster order processing times, improved inventory management, and seamless capacity scaling during high-demand seasons, all without disrupting daily operations. In food and beverage manufacturing, hygienic conveyors and automated ingredient handling have led to dramatic reductions in contamination risks and compliance costs. Logistics firms are leveraging real-time data to avoid bottlenecks and optimize delivery routes, resulting in lower costs and higher customer satisfaction. As operations grow and diversify, investments in modern handling solutions prove essential for staying agile in a competitive market. Ultimately, organizations that embrace these advancements can adapt quickly to shifts in customer expectations and market trends, maintaining a crucial edge over competitors who lag.

The evolving landscape of industrial and commercial workspaces demands smarter, safer, and more responsible material handling strategies. By integrating automation, harnessing IoT intelligence, adopting ergonomic and safety improvements, and embracing sustainable practices, organizations can achieve unrivaled operational efficiency, reduce risks, and promote long-term growth. The future of material handling rests in holistic, technology-driven solutions that prioritize both people and the planet. Companies that invest in these innovative strategies today will position themselves not only for immediate improvements but also for sustained success well into the future, regardless of what challenges tomorrow may bring.